Products

▼Open system

Brief Introduction

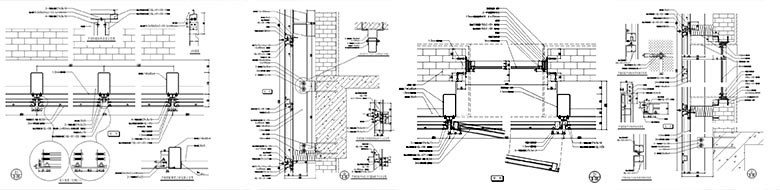

The open aluminum facade system is a non-adhesive process for the aluminum plates at the joints, which enables the air in the air layer behind the aluminum panel to exchange smoothly through the joints, thus achieving good heat insulation and sound absorption effects. The system is of a beam-free structure. The upright post is designed to be U-shaped. M8 stainless steel bolts are installed on the upright post. A 2mm thick anti-seismic and anti-noise nylon sleeve is placed on the screw rod. U-shaped aluminum is used as a reinforcing rib on the aluminum panel. The aluminum panel is hung on the M8 hang-up coupling screw rod through the flange of the aluminum panel.

2. Coating Type

The surface can be treated by fluorocarbon coating, powder coating, wood grain imitation thermal transfer printing, fluorocarbon pre-roll coating, electrophoresis, chromization, etc. Different treatment types make metal panels have different decorative effects and their service life is also different.

3. Product Features:

The upper part of the plate is fixed on the U-shaped groove of the upright column by screws, which on one side is fixed, while on the other side is provided with a long round hole on the flange of the aluminum plate, so that the influence of heat expansion and cold contraction on the plate can be digested transversely.

The inside rainproof inter-layer is composed of a 1.5mm thick waterproof back plate (usually galvanized steel plate) and 50mm thick insulation cotton. The insulation cotton is fixed on the back plate by cotton nails. Pinhole aluminum foil is arranged behind the insulation cotton, which can volatilize the water vapor that may be generated and ensure that the insulation cotton is in a dry state.

The 20mm joint between the aluminum panel is completely open, making the air chamber between the panel and the back panel communicate with the outside. The pressure in the air layer is basically equal to the outside pressure, forming an equal pressure chamber, which inhibits the reverse circulation of water due to pressure difference. A small amount of leakage water and condensed water are discharged out of the chamber through drain plates (also serving as air barriers) arranged on each layer, thus forming a complete drainage system. As the rain-proof inter-layer is arranged on the vertical rod keel, two cavities are formed between the aluminum facade and the wall, thus enjoying better thermal insulation performance. The air layer behind the aluminum panel reduces heat conversion through air convection, which can reduce building cooling costs in summer and heating costs in winter.

The air tightness of facade is realized by glue sealing between waterproof inter-layer and keel. In order to achieve better air isobaric effect, we have set up an air baffle on each floor. By separating the air, each layer forms an equal pressure air chamber, which effectively reduces the air pressure difference caused by height change. At the same time, the gas barrier also serves as a drainage panel, and condensed water and leakage water can be discharged in layers.

Because the panel is hung on the screw through the hanging plate, only the upper side is fixed and positioned by the screw, and the plate is in a free hanging state under the action of gravity, the stress of the plate and the ability to resist thermal expansion and cold contraction reach better performance.

High degree of machining and fewer on-site machining and manufacturing procedures ensure the installation accuracy of the system and the smoothness of its surface.

And the condensed water can be volatilized during the circulation of the air layer. As the joint adopts non-gluing technology, the contamination on the surface of the aluminum plate is reduced and the surface of the aluminum panel is kept clean for a long time. The regular cleaning cost of the outer surface of the facade is consequently reduced.

4. Specifications:

Commonly used for processing are 2.0mm, 2.5mm, 3.0mm thick metal panel, including aluminum panel, copper panel, other composite panel, etc.